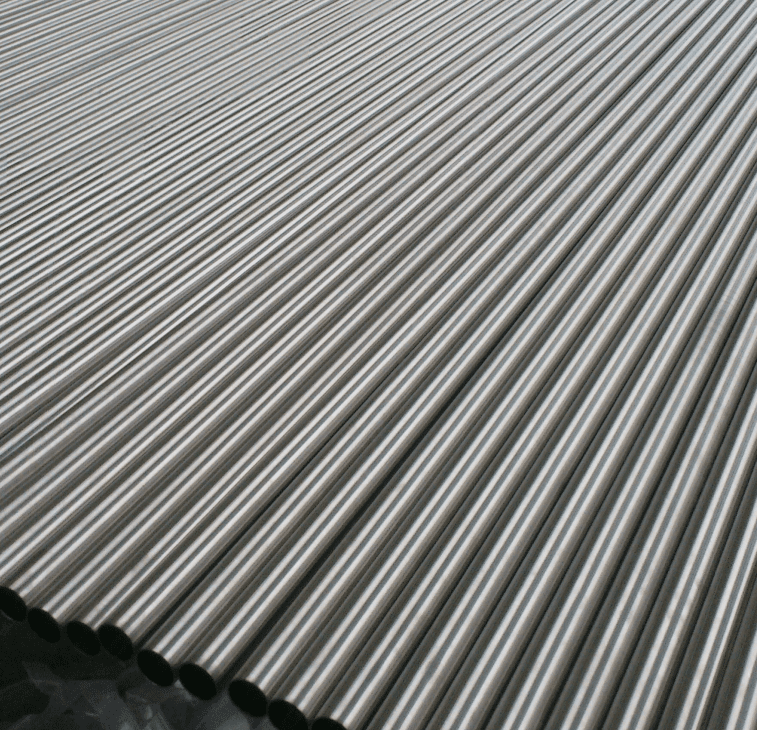

Polished Stainless Steel Tubing

Polished Stainless Steel Tubing is the main tubing line for a piping system, the surface is polished to meet the requirement of high purity hygienic requirment from food, beverage, beer, winery, pharmacy, cosmetics etc.. Generally, food grade stainless steel tubings are made in stainless steel 304 and 316L, but we provide other grade too such as hastelloy C22, 316Ti, Titanium and nickel alloy etc.

We offer both seamless stainless steel tubes and welded food grade stainless steel pipe to ASTM A270, and size is up to 12″. Inner and outer surface is polished to meet the high purity requirement of hygienic industries. Wellgreen sanitary is ability to supplying qualified sanitary tubings comply to your your condition and FDA,GMP requirement.

Material:

Stainless Steel 304, 316L or En.1.4301, 1.4404 etc. Specified grade is available.

Strength:

- Material of stainless steel 316L and 1.4404 is from reputed mill to guarantee the chemical composition and mechanical properties of sanitary tubings. Material certificate will be submitted to orders.

- Heat Treatment of solution annealing for the sanitary tubings and fittings are available. The heat treated will be relief stress which caused by cold forming of fabrication, to improve the corrosion performance.

- High precision on dimension and wall thickness.

- Bright annealing is available.

- Fast delivery for general specification to meet your needs well in time.

- Both seamless and welded sanitary tubings are available to meet your different usage.

- Multiple grade upon your requirement.

- Length is up to 12 meters.

- Min. order quantity of sanitary tubings is from 300Kgs.

- Offer industrial pipe and tubes according to order.

- Surface roughness condition < Ra 32.

Quality & Inspection:

- PMI test to verify material grade.

- Dimension controlling.

- Visual and surface 100% examination before shipment.

- End protected for shipment.

- Packed in wooden case (Free-fumigated).

Polishing Opinion:

Mechanically is available to meet your high quality requirement on the surface of sanitary tubings. Outer and Inner surface can be treated complied to specified needs, and to meet FDA, GMP requirement.

- Inner and Outer Polished : Ra 20 (0.5?m), Ra 25 (0.6?m) , Ra 32 (0.8?m) or Grit 180, 200, 320 etc.

- Inner polished and external pickled

- Inner pickled and external polished

- Both Internal and external pickled

- Internal and external bright annealing solutions

Application:

Food, Brewery, Beverage, Dairy, Pharmaceutical, Biopharma etc.

| Standard | ASTM A270, ASTM A249, ASTM A269, ASTM A213, EN/DIN etc. |

|---|---|

| Material | T304, T316L, EN 1.4301, EN 1.4404 etc. |

| Size | Outside Diameters: 1/2″ ~ 12″,Wall Thickness: 0.020″ ~ 0.250″ |

| Surface | Descaled finish, Mirror polished on requested |

| Application | Food, Brewery, Beverage, Dairy, Pharmaceutical, Fine chemical, Cosmetic etc. |

| How to order | *Part Name*Dimension*Material*Quantity*Polish requests for OD/ID |

Dimension Table of Sanitary Tubing – Polished Stainless Steel Tubing – Food Grade Stainless Steel Pipes

| ISO/IDF | SMS-DS | 3A | ISO 2037(JIS G3447) | ||||||||

| Size | D | t | Size | D | 1 | 2 | Size | D | t | Size | t |

| 1/2″ | 12.7 | 1.5/1.0 | 25 | 25 | 1.25 | 1.5 | 1/2″ | 12.7 | 1.65 | 12 | 1.0 |

| 3/4″ | 19.1 | 1.5/1.0 | 32 | 32 | 1.25 | 1.5 | 3/4″ | 19 | 1.65 | 12.7 | 1.0 |

| 1″ | 25.4 | 1.5/1.2 | 38 | 38 | 1.25 | 1.5 | 1″ | 25.4 | 1.65 | 17.2 | 1.0 |

| 1.25″ | 31.8 | 1.5/1.2 | 51 | 51 | 1.25 | 1.5 | 1 1/2″ | 38.1 | 1.65 | 21.3 | 1.0 |

| 1.5″ | 38.1 | 1.5/1.2 | 63.5 | 63.5 | 1.5 | 2.0 | 2″ | 50.8 | 1.65 | 25 | 1.2/1.6 |

| Ø45 | 45.0 | 2.0 | 76 | 76 | 1.6 | 2.0 | 2 1/2″ | 63.5 | 1.65 | 33.7 | 1.2/1.6 |

| Ø48 | 48.0 | 1.5 | 89 | 89 | 2.0 | 2.0 | 3″ | 76.2 | 1.65 | 38 | 1.2/1.6 |

| 2″ | 50.8 | 1.5 | 101.6 | 101.6 | 2.0 | 2.0 | 4″ | 101.6 | 2.1 | 40 | 1.2/1.6 |

| Ø57 | 57.0 | 2.0 | 6″ | 152.4 | 2.8 | 51 | 1.2/1.6 | ||||

| 2.5″ | 63.5 | 2.0 | 8″ | 203.2 | 2.8 | 63.5 | 1.6 | ||||

| 3″ | 76.2 | 2.0 | 10″ | 254 | 3.4 | 70 | 1.6 | ||||

| 3.5″ | 89.0 | 2.0 | 12″ | 305 | 3.4 | 76.1 | 1.6 | ||||

| 4″ | 101.6 | 2.0 | 88.9 | 2.0 | |||||||

| Ø108 | 108.0 | 2.0 | 101.6 | 2.0 | |||||||

| 4.5″ | 114.3 | 3.0 | 114.3 | 2.0 | |||||||

| Ø133 | 133.0 | 3.0 | 139.7 | 2.0 | |||||||

| Ø159 | 159.0 | 3.0 | 138.3 | 2.6 | |||||||

| Ø204 | 204.0 | 3.0 | 219.1 | 2.6 | |||||||

| ISO/IDF | SMS-DS | 3A | ISO 2037(JIS G3447) | ||||||||

| Size | D×t | D×t | D×t | D×t | Size | t | Size | t | Size | D | t |

| DN10 | 12×1.0 | 13×1.5 | 14×2.0 | 12×1.5 | 12.7 | 1.2 | 26.9 | 1.6 | 8A | 13.8 | 1.65 |

| DN15 | 18×1.0 | 19×1.5 | 20×2.0 | 18×1.5 | 15.88 | 1.2 | 33.7 | 2.0 | 10A | 17.3 | 1.65 |

| DN20 | 22×1.0 | 23×1.5 | 24×2.0 | 22×1.5 | 19.05 | 1.2 | 42.4 | 2.0 | 15A | 21.7 | 2.1 |

| DN25 | 28×1.0 | 29×1.5 | 30×2.0 | 28×1.5 | 25.4 | 1.2/1.6 | 48.3 | 2.0 | 20A | 27.2 | 2.1 |

| DN32 | 34×1.0 | 35×1.5 | 36×2.0 | 34×1.5 | 38.1 | 1.2/1.6 | 60.3 | 2.0 | 25A | 34.0 | 2.8 |

| DN40 | 40×1.0 | 41×1.5 | 42×2.0 | 40×1.5 | 50.8 | 1.2/1.6 | 76.2 | 2.0 | 32A | 42.7 | 2.8 |

| DN50 | 52×1.0 | 53×1.5 | 54×2.0 | 52×1.5 | 63.5 | 1.6/1.6 | 88.9 | 2.0 | 40A | 48.6 | 2.8 |

| DN65 | 70×2.0 | 70×2.0 | 76.2 | 1.6/1.6 | 114.3 | 2.0 | 50A | 60.5 | 2.8 | ||

| DN80 | 85×2.0 | 85×2.0 | 101.6 | 2.0 | 139.7 | 2.0 | 65A | 76.3 | 3.0 | ||

| DN100 | 104×2.0 | 104×2.0 | 114.3 | 2.0 | 168.3 | 3.6 | 80A | 89.1 | 3.0 | ||

| DN125 | 129×2.0 | 129×2.0 | 139.7 | 2.6 | 219.1 | 3.6 | 90A | 101.6 | 3.0 | ||

| DN150 | 154×2.0 | 154×2.0 | 168.3 | 2.6 | 100A | 114.3 | 3.0 | ||||

| DN200 | 204×2.0 | 204×2.0 | 219.1 | 125A | 139.8 | 3.4 | |||||

| 150A | 165.2 | 3.4 | |||||||||

| Series1 series2 Series3 series4 | 200A | 216.5 | 3.4 | ||||||||

*We also provide stainless steel tubes and pipes with unpolished and pickled surface to meet industrial usage.

* For more information and specification about sanitary tubings, please contact us here.

Polished Stainless Steel tubing catalog

ASTM A270 -2015 -en – Stainless Steel Sanitary Tubing